Biosensors

Amperometers and Potentiometers

Thanks to its high level of quality, Topflight Italia SPA was able to obtain homologation

Biosensors

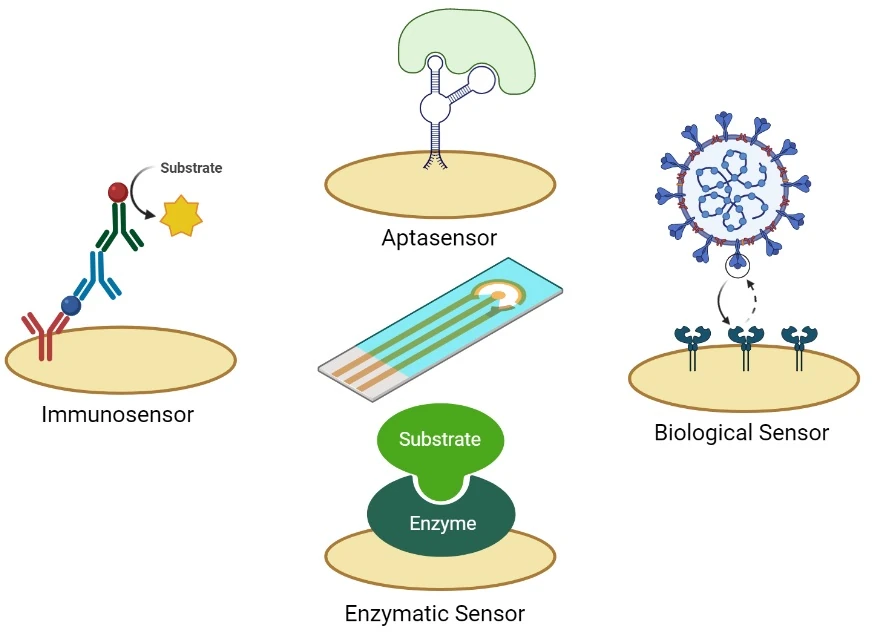

A new methodology is gaining ground in diagnostics using biosensors, devices that can detect the presence of bacteria, viruses and molecules. Topflight Italia, is focused on the production of biosensors, based primarily on electrochemical signal transduction. Therefore, sensors are manufactured that require a printed circuit board coupled to a specific reagent.

Technically, the biosensor works with a biological element, called a bioreceptor, attached to a substrate that is able to transform a specific biological reaction, which has taken place between the biological element and the sought-after element, into a signal detectable by the transducer. The transducer is able to interpret changes in the substrate, thus reproducing an electrical signal that can then be observed and measured.

Topflight Italia’s primary technology, is to deposit conductive and non-conductive materials onto layers of plastic material to form electrodes, using screen printing, laminating, assembling and stamping techniques. Topflight Italia, is not only able to print conductive materials, but also to deposit reagents with a very accurate and precise deposition, using unique techniques. The development of biosensors is now aided by the possibility of signal acquisition and processing by computer and ‘pattern recognition’ methods.

Specifications

All biosensors produced by Topflight are custom-made, i.e. made to a drawing supplied by the customer. If the biosensor is requested by the customer in an intermediate state, it will be supplied in multiple sheets according to the customer’s requirements. If, on the other hand, the finished biosensor including reagents is requested, then it will be supplied in single, packaged form, in which case Topflight will request the use and performance specifications for that reagent. Thanks to the use of highly sophisticated machinery and equipment, Topflight is able to guarantee the production of high-precision biosensors with tight processing tolerances.

The achievable tolerances for our sensors are listed below:

automatic printing: ± 0.1 mm

lamination tolerances: ± 0.2 mm.

die-cutting with respect to printing with optical vision systems: ± 0.10 mm.

cutting width: ± 0.04 mm

Composition

The chemical biosensor normally consists of the transducer and the receptor. The transducer is that part of the sensor that converts the chemical signal into a signal that can be observed and measured. The biosensors produced by Topflight are composed as follows: material layers, conductive pastes, reagents. All layers that make up such a transducer start from roll and continue in sheet form in order to achieve tighter processing tolerances in the printing and stamping stages.

It is preferable to use materials recommended and produced by Topflight for making the sensor, as these are special stabilised materials that have already been tested for use in the biosensor field, based on their own production processes. The materials normally used are polyester and polycarbonate. They undergo special treatments to make them suitable for biosensor production. Topflight is however willing to use special materials outside its own range if requested by the customer.

The pastes mainly used for printing are conductive and are as follows

– conductive graphite

– conductive silver

– UV insulators

– other special materials

Topflight boasts a special and exclusive reagent deposition system. These can be developed by the customer, who will then provide all storage and processing specifications, or they can be produced in synergy with Topflight. In fact, thanks to close collaboration with competent and prestigious research institutes, it is able to provide maximum assistance and expertise in the formulation, development and fine-tuning of specific reagents.

Once the formula has been identified, Topflight produces the reagent directly in its own laboratories.

Search

At Topflight, the Research sector is considered primary and strategic. The production of biosensors requires advanced research methodologies applied to materials and Topflight has set up its processing structure so that all stages, from design to production process, are within high Quality Control standards.

Topflight relies both on its own laboratories and on close collaboration with competent and prestigious research institutes to develop specific reagents requested by customers. In fact, Topflight makes all its expertise and research laboratories available to its customers for the study and fine-tuning of the sensor, setting up with them a relationship of synergy and collaboration to complete the development of the finished product.

Topflight, using state-of-the-art technologies and processing methods in the production of its biosensors, is able to supply a technologically advanced finished product at truly competitive costs. In Topflight the customer therefore finds a valid and valuable partner able to help and assist him throughout the research and development phase of his product.

Production process

The production process consists of seven steps:

– SCREEN PRINTING

– First VISION TEST

– First ASSEMBLY

– REAGENT DEPOSITION (where required)

– Second ASSEMBLY

– Second VISION TEST

– PACKAGING (where required)